Design Parameters That Impact Elevator Safety Set Performance

In the modern fast-paced world, elevators are a common feature in residential and commercial buildings. Underneath every smooth and secure ride, there is an advanced safety system. Of these, the safety set of the elevator is very important in ensuring passenger safety, stability, and the smooth operation of the elevator. For building owners, contractors, and architects, being aware of the design parameters influencing the performance of the safety set is highly important.

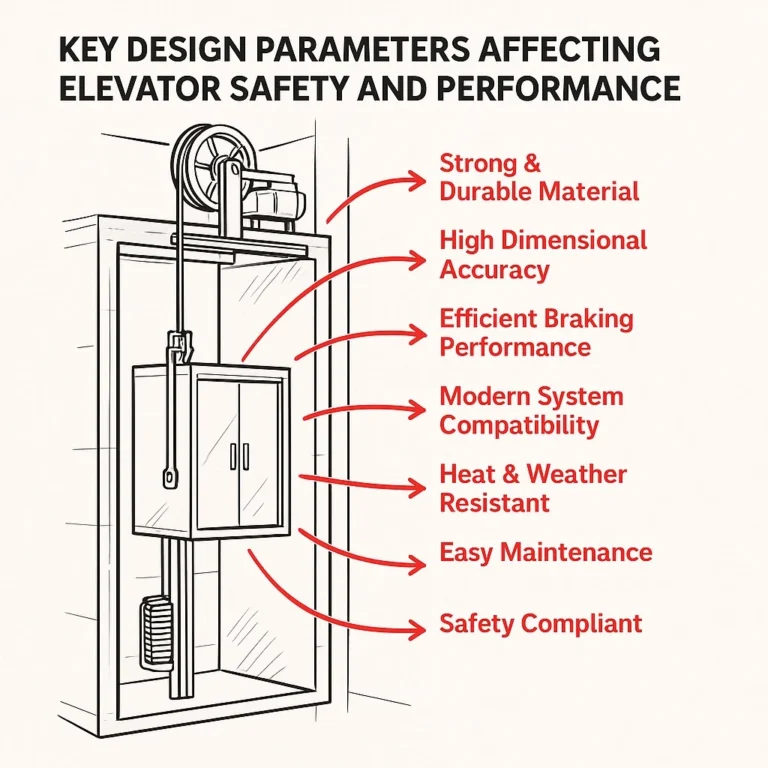

Key Design Parameters Affecting Elevator Safety and Performance

1. Material Strength and Durability

The basis of any safety set is the material used. Top-quality alloys, cast iron, or steel are usually utilized to impart ultimate strength and longer service life over the long term. The design has to be able to withstand heavy loads, vibrations, and fluctuating operating conditions without impairing safety. An ill-designed system with inferior quality materials can accelerate wear, resulting in hazards and greater maintenance expenses.

2. Accuracy of Dimensions and Tolerances

Safety sets demand careful engineering accuracy. Even the tiny flaw in dimension or tolerance can result in faulty operation or failure. An elevator safety set company makes sure each and every component is designed to precise specifications, providing a smooth fit in the elevator system. This precision improves productivity while reducing extra friction and wear.

3. Efficiency in Braking System

One of the greatest concerns of a safety set is the braking capacity. In cases of sudden power outages or emergency braking, the braking mechanism slows down the elevator to a safe stop. Smooth yet firm braking should be accounted for in the design so that neither hard jerks nor overshooting occurs. New generation brake shoe materials and heat-resistant paint are being more widely employed to enhance performance.

4. Load Capacity and Stress Distribution

Various buildings require elevators with different load capacities,starting from tiny residential lifts to large freight elevators. The safety set should be made to endure certain weight ranges and even out stress among its elements. Ignoring this factor results in shortened lifespan or risky operation. A good manufacturer of lift safety sets such as top manufacturer applies samples under harsh conditions of stress to ensure reliability.

5. Compatibility with Modern Control Systems

Modern elevators are equipped with intelligent systems that continuously track performance. Intelligent controls must be compatible with safety sets so that anomalies are detected quickly and corrective measures taken immediately. This compatibility enhances not only safety but also operational efficiency with less downtime and fewer maintenance visits.

In search of high-quality, high-performance safety sets?

Reach out to Veer Elevator today,your go-to expert in next-generation elevator safety solutions.

6. Heat Resistance and Environmental Factors

Elevator safety sets usually undergo frictional heat during operations. Parameters of design like heat dissipation, lubricating systems, and high-temperature resistance have a significant influence on their performance. Moreover, resistance to dust, moisture, and environmental changes assures reliable safety in changing operating conditions. This is the reason why Veer Elevator also focuses on durable elevator safety components and parts that promote system reliability.

7. Maintenance and Inspection Ease

Ease of maintenance should also be catered to by practical design. Safety sets that are hard to inspect and repair can lead to prolonged downtime and higher operational expenses. Properly engineered systems by an established elevator safety set manufacturer enable easy inspection, replacement, and maintenance without sacrificing safety standards. In conjunction with this, top manufacturers offer elevator spare parts and safety solutions for hassle-free maintenance operations.

8. Safety Standards Compliance

Elevators are operated under strict local and international safety standards. A trusted set design for safety must meet standards like EN81, IS, or any regional standard. This does not just guarantee law compliance but also higher reliability and safety confidence for passengers. Suppliers follow these standards so that all products can meet international safety standards.

Safety in elevators is not a matter of negotiation and the efficiency of a safety set relies on a precise balance of design parameters including material quality, braking performance, stress distribution, and global standards compliance. Through collaboration with a seasoned elevator safety set manufacturer like Veer Elevator, building owners and contractors can be assured to deliver safe, smooth, and reliable elevator services.

WhatsApp us